Variables of Laser Cutting Create Unique Ventilation and Collection Options

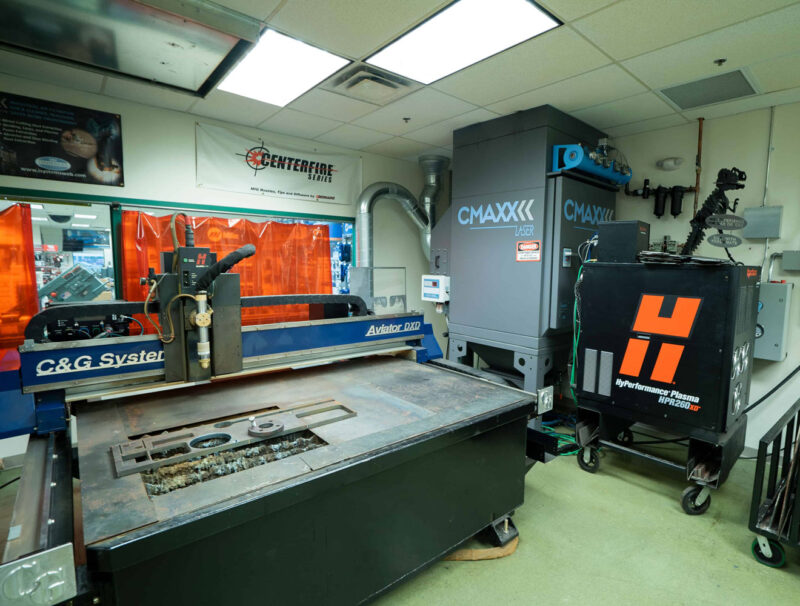

While the process of laser cutting may be largely robotic requiring less direct employee involvement, air quality variables still exist. Whether it’s a CO2 and fiber laser cutting process, the wide variety of applications using laser cutting create variables.

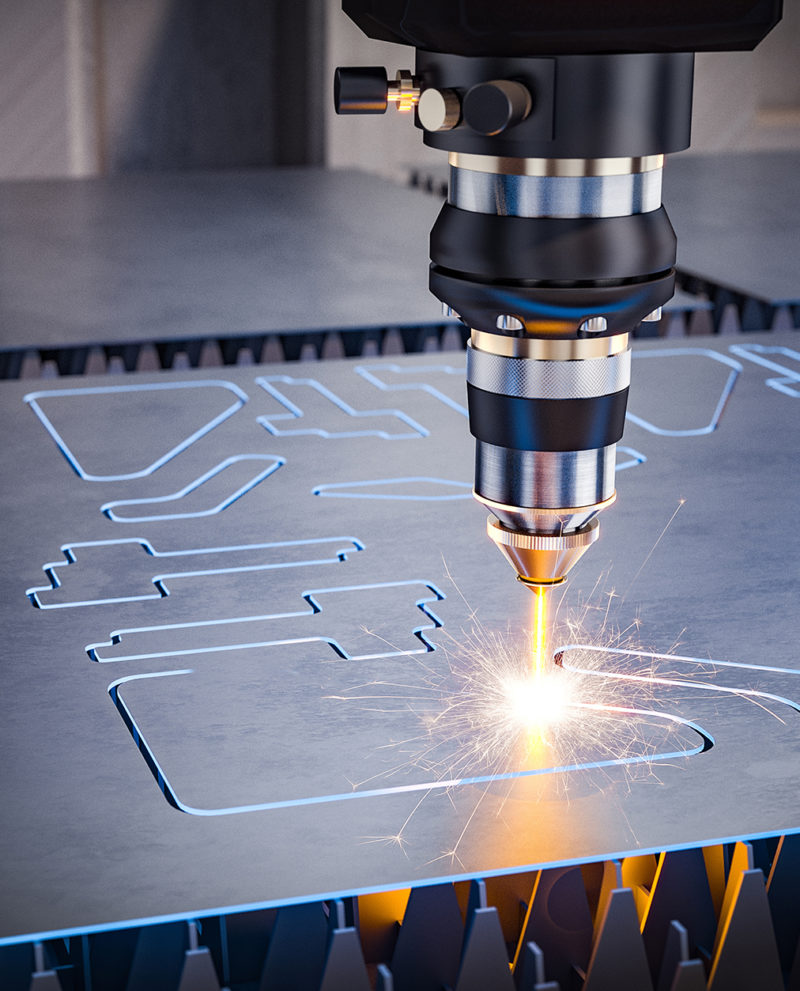

One variable is constant — all lasers produce very fine dust and fumes.

The good news is, installing a ventilation system for a laser is typically more straightforward than for welding or plasma cutting. Most high-efficiency fume extraction systems even come ready to plug in and use.

Choosing the correct system is imperative. Summit understands how to satisfy the ventilation and collection needs of different lasers in different applications.

We’ll properly address your company’s laser cutting hazards.

Ultrafine Dust Particles Are Dangerous

The fumes emitted during the laser cutting process contain dust particles that are smaller than 10 microns. They can easily infiltrate electronics and machinery, and be absorbed into workers’ lungs.

There are serious consequences caused by something so small.

Laser cutting process fumes have serious potential health consequences to your employees, including lung cancer and manganism – a neurological disorder tied to Parkinson’s disease.

Factors to Consider Before Choosing a Laser Cutting Ventilation Solution

A ventilation system can only be as effective as the planning behind it. Start by asking these questions.

- What type of metal will you be cutting, and is that type of metal dust combustible?

- Does your company use CO2 or fiber lasers? What is the wattage?

- How many laser cutting stations does your company operate?

- Will you be setting your laser to operate during off-hours?

- Which option is the most energy-efficient and cost-effective?

Did you know metal dust particles left uncollected easily find their way into exposed eyes?

It’s a common cause of injury in factories. Source capture can help

Helpful Tips Prior to Selecting a Laser Cutting Ventilation Solution

Laser cutters are sophisticated machines with a certain amount of simplicity built into their design. The plug-and-play nature of lasers and corresponding fume extraction systems makes pairing the two seemingly straightforward.

It is crucial that dust and fumes are collected from the source and that particles are properly stored and disposed. The complete unit will still require strict attention to detail and ongoing maintenance to ensure both are operated safely.

Considerations:

Noise: The sound of exhaust fans in a fume extraction system can create a loud and taxing workplace. Customizable silencers can be built into the system to bring the noise level down to a desirable level.

Filters: For laser cutting, nanofiber filter media is the recommended choice. This substrate is flame-retardant and designed to keep fine laser dust from penetrating deep into the crevices of the filter. These filters are easier to clean, show slower equipment wear, and contribute to better energy efficiency.

Filter configuration: Vertically mounted filter cartridges tend to have less dust buildup than horizontally mounted versions. Minimized buildup means longer filter life and a decreased likelihood of dust combustion.

Intended use: While this may sound obvious, it is vital that you do not use the laser cutter fume extraction system for any other fume extraction purpose. Using the system to cut potentially flammable or otherwise hazardous materials could result in dangerous situations and damage.

The Fire and Explosion Hazards of Laser Cutting

Flammable oil is sometimes used to prevent corrosion in the raw materials being cut with lasers. That alone makes fire hazards a real concern. Now couple it with unoxidized metal fumes which can be combustible. The potential for a calamity becomes very real.

Explosive dust is a hazard to be aware of in any facility where metal cutting takes place. Several types of metal dust are combustible, creating a risk of explosion in the workplace. Read more on finding out if your dust is combustible and if it can explode.