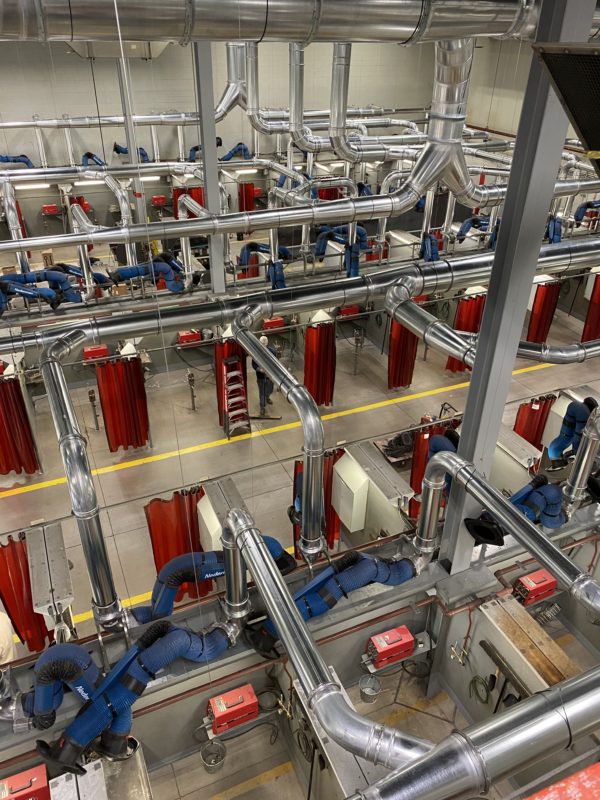

Whether Welding by Machine or Person, Ventilation is Crucial

By its very nature, welding is a process that creates a hazardous environment. It produces a significant amount of smoke, dust and heat.

Even in laser welding operations, where the work is generally done by a machine, it is still crucial to ensure that welding ventilation systems are keeping the surrounding air free of dangerous particles.

No two welding facilities are the same and as such no two facilities have the same hazards.

Size and configuration of a facility certainly factor in, but you must also consider that MIG, TIG, arc, and laser welding all present fume and temperature considerations that will affect your indoor air quality differently.

Welding Ventilation System Considerations

A ventilation system for welding can only be as effective as the planning behind it. When it comes to compliance and safety, you must ask all of the pertinent questions and consider all of the little factors that make your facility unique.

- How tight is the floor space between your welding stations?

- What type of welding will be taking place, and what atmospheric challenges will it present?

- Will fume extractors for individual stations affect production?

- Would a hood be effective, while still allowing welders to move freely?

- Which option is the most energy efficient and cost effective?

These questions are just the beginning. The process of designing the correct source capture or ambient air system is complex and not to be taken lightly.

Source Capture vs. Ambient Air Systems

When it comes to welding, an ambient air system is not enough of a solution to mitigate dangers specific to welding. Either source capture welding fume extractors or overhead and side draft hoods are typically the answer.

Learn more of the pros and cons and how to navigate fume extraction options.

A Report Card of Hazardous Fume Presence

Comparable Welding Businesses

Plant A and Plant B are both 60,000 square foot rooms with 50 foot ceilings.

| Plant A | Plant B | |

|---|---|---|

| EMPLOYEE BREATHING ZONE | AMBIENT AIR VENTILATION | SOURCE CAPTURE |

| Zinc Oxide | 14,000 mc | 0 mc |

| Manganese | 8,000 mc | 0 mc |

| Hex Chrome | 27,000 mc | 0 mc |

| Hazardous Fume Presence Grade | F | A |

Plant A uses an ambient air ventilation system operating at 30-40,000 CPM (cubic feet per minute) in order to maintain optimal indoor air quality. The air is only filtered after it has entered the welders’ breathing zones and puts all employees at risk.

Plant B uses source capture welding fume extractors requiring approximately 1,000 CPM per welder to maintain air quality. Company experiencing substantial energy cost saving over its ambient air system and achieved less hazardous workstations for their welders.

Hazardous Welding Fumes Endanger Employee Health

The contents of hazardous welding fumes have been known to create headaches among welders, along with more serious injuries including lung cancer and manganism.

Learn how hazardous ignoring fume extraction really is to your business.

Now call Summit. We will get your facility within OSHA guidelines and keep your employees safe.

Did you know metal dust particles left uncollected easily find their way into exposed eyes?

It’s a common cause of injury in factories. Source capture can help.