Explosive Dust Protections are Essential in the Workplace

The presence of combustible and potentially explosive dust in a workplace is a hazard to the health and safety of your workers and to the workplace, itself.

Hundreds of industrial explosions have resulted in deaths, injuries, and millions of dollars in property damage. Understanding the elements that make up a combustible dust explosion and knowing how to address them are critical to maintaining an industrial facility.

To navigate explosive dust, tap into the knowledge experts at Summit.

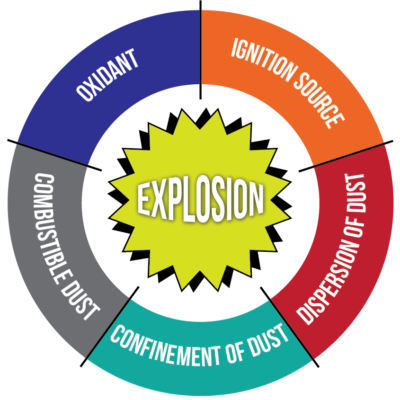

The Five Elements of a Dust Explosion

There are five main components in what is called the “dust explosion pentagon”.

- Combustible dust

- An ignition source

- Oxygen in the air

- Dispersion of the dust in sufficient concentration to be explosive

- Containment of the dust cloud within a confined or semi-confined vessel or area

When the components come together under one roof, they create volatility and the real potential for fire or explosion.

A company must address all of the contributing factors, or they run the risk of serious incident.

In facilities where some or all of these conditions are common, preventative steps are necessary to avoid a dust explosion. Call upon Summit to help and design an explosive dust protection system.

How will I know if “contributing factors” to a dust explosion are present in my facility?

To avoid a combustible dust explosion in your facility, you must first determine whether you have combustible dust. Working with a reputable testing company to conduct a combustible dust hazard analysis of your facility is an imperative first step.

This test will determine what kind of dust is produced by your various industrial processes, and whether it is explosive. Summit works with Fauske, a very reputable third-party testing company, to simplify the testing process for our customers.

Specific Dust Explosion Prevention Measures

Depending on the specific circumstances in your facility, a wide variety of dust explosion prevention procedures and equipment could become necessary.

Summit will help you navigate the needs and find the correct combination of measures to keep your workers, and your facility, free of harm.

- Spark Detection

- Spark Suppression

- Abort Dampers

- Explosion Venting

- Explosion Suppression

- CO2 Fire Extinguishing

- Flameless Explosion Venting

- Backdraft Dampers

What Must be Done to Avoid Dust Explosions?

Summit has the expertise and experience to work with you from a mandatory explosive dust hazard analysis through strategizing about how to best address surfaced hazards. We will design the right system and install it … and provide ongoing assistance in the future.

With stringent and changing regulations regarding dust collection explosions to contend with, having a partner in Summit will prove invaluable.

The Kst and Pmax values of your dust will indicate what dust collection, explosion ventilation, and fire suppression system your company will need. We then look to “future proof” your system with what new guidelines may be on the horizon.

Rest assured. We will provide the correct dust and spark collection system, and the proper explosion suppression or explosion venting solutions needed.

Don’t just take our word for it. We are proud of our 98.9% customer satisfaction rate. Experience and comprehensive industry knowledge does matter.

NFPA and OSHA Standards

The National Fire Prevention Association (NFPA) and Occupational Safety and Health Administration (OSHA) have established standards for combustible dust and how to avoid an explosive dust situation.

The NFPA has established seven standards that pertain to combustible and explosive dusts, and dust collection which a company is obligated to understand and comply to. NFPA Seven Standards »

OSHA has defined the types of dust that can potentially be combustible and explosive, and the necessary measures to prevent fire and explosion from happening. Download their poster here »

It’s a lot to take in. We understand. Summit is here to help navigate the standards and ultimately engineer a combustible dust collection system to give your organization explosive dust protection … and keep your business within compliance.